Bio-coal from organic waste through BSP technology

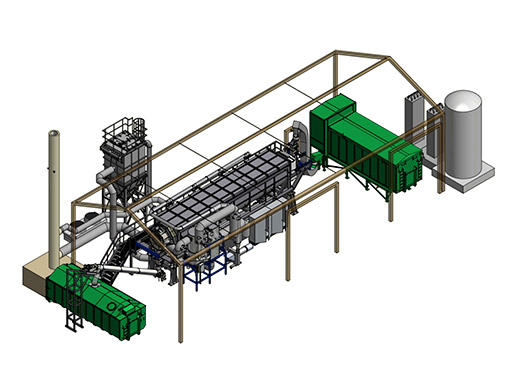

Schematic diagram of the BSP demo plant

During the process, the biomass is thermally treated for about one hour at 300 – 350 °C in a steam atmosphere. The target product is a carbon-enriched bio-coal, which can be used in various applications and as a raw material for production of activated carbon. The applications include use as a bio-fuel, as a soil conditioner for degraded soils and as a CO2 sink. Advantageous compared to other recycling technologies are the moderate process parameters (atmospheric pressure, comparatively low temperature) and low energy expenditure per unit biomass treated. Additionally a dry, inert and easily storable bio-coal is produced from the wet biomass processed.

On contract from EnBW AG, Live Energies GmbH is currently building a demonstration plant on the site of a composting facility. The plant will have a throughput of at least 2,000 t/a and will utilise various biogenic waste streams produced during composting. By using the BSP technology the cost-intensive disposal of such waste streams can be avoided and at the same time a valuable raw material (bio-coal) can be produced. The rotary kiln plant with connected waste gas heat re-utilisation will start regular operation in spring 2020.

Established BSP plant at the composting facility

Publications

- Jatropha – Potential of biomass steam processing to convert crop residues to bio-coal and thus triple the marketable energy output per unit plantation area. https://www.sciencedirect.com/science/article/abs/pii/S0926669019303152

Removal of nutrients from liquid manure with bio-coal

Liquid manure is being currently distributed in nearby fields

Intensive livestock farming causes environmental problems due to the nutrient-rich excrements produced by the livestock. Presently the waste from livestock farming is being applied to the soil either directly or as biogas digestate resulting in excessive nutrient accumulation in the soil and groundwater. The manure usually has high water content of over 90%. Even after producing biogas, the slurry contains high percentage of water rich in various nutrients. This high volume with less concentration of the mineral nutrients limits transportability of the manure, resulting in application in the vicinity of the farms itself. A transportable, concentrated mineral nutrients from the liquid manure can avoid such regional over-nutrition and can provide organic fertiliser for other areas.

Live Energies GmbH is cooperating with the State Institute of Agricultural Engineering and Bioenergy at the University of Hohenheim to evolve methods to remove excess nutrients from liquid manure and concentrate them to generate transportable organic manure. During this project various methods to remove nutrients from manure and to bind them with bio-coal will be developed and tested to evolve standardised methods to remove problem nutrients from the liquid manure and to produce easily transportable organic fertiliser.